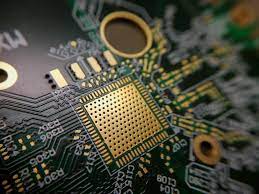

For a little PCB prototyping business bent on serving a number of the best-known and most respected tech brands on the earth, quick turnaround is quite a marketing gimmick – it is a promise. PCB prototype assembly is by no means an easy activity, and small, time-consuming hang-ups can develop into lost orders and angry customers in an industry where 48-hour turnarounds are the norm.

In order to be ready to reliably produce results on such short time frames, SMT PCB Assembly plants must optimize nearly every aspect of their workflow for speed and consistency. At the center of this need is an inherent conflict between maximizing the assets and resources you already own or adding additional assets and resources to your environment.

Essentially, what fast-turnaround PCB assemblers want to understand is whether or not they ought to hire additional help and make more use of their machines, or buy newer, better machines which will allow them to make the foremost of their current staff.

Imperfectly Optimized PCB Planning Systems

Before jumping into the difficulty of whether manpower or machine power really generates fast turnarounds, we’d like to take care that the PCB planning system itself is already performing optimally. As William Ho asserts, component placement is that the bottleneck of any PCB production line.

Essentially, that bottleneck is created of two parts – component sequencing and feeder arrangements. PCB manufacturers must choose the optimal sequence of components and so assign them to the acceptable feeders.

There are nearly infinite ways in which PCB component sequencing and feeder arrangements may be approached. Finding the truly most effective solution is solely not feasible during a business context – not, at least, with current computational technology, and definitely not within a two-day timeframe.

PCB assemblers on a decent deadline use genetic algorithms to work out near-optimal planning systems without getting lost on the thanks to the “perfect” solution. While this can be not a controversy which will be solved with today’s technology, it is important to recollect that no current PCB assembly process is perfectly efficient. This becomes an increasingly complicating factor for high-volume PCB prototype companies.

More Machines Means More founded Time

Knowing that any given PCB assembly process must be but perfectly efficient, we are able to address time constraints on workflow processes. SMT PCB Assembly aren’t plug-and-play devices. Even efficient machines require changeovers of a minimum of an hour – if you run eight to 10 setups every week, which means that you’re losing a whole day in production time each week.

Changeover times can become an enormous drag on production, especially when handling tight turnarounds. Time, once lost, can’t be recovered, and each second of your time saved boosts revenue. Since SMT machines can encounter nearly infinite production possibilities on one run, and are often tasked with making multiple runs per day, any changeover time is downtime. A UIC shows in an exceedingly simple set of graphs in line with SMT machine revenue generating time, every second counts – an hour of downtime for a line that generates $10 million yearly costs $5000.

While there are always ways to enhance the efficiency of a PCB line, there’s no thanks to account for $5000 in unnecessary losses. Considering that some SMT machines can take up to four hours to line up for one run of a prototype PCB, making the foremost of every workday is out and away the higher option. Moreover, installing additional production lines doesn’t affect the productivity of every individual line. While it should appear to enhance PCB assembly turnaround, adding more lines and workers may cost quite its worth if overall production volume doesn’t also increase. For this reason, keeping workers late or perhaps hiring an additional shift is out and away the higher option.